I tried printing with a raft and Siboor glue. It printed for eight hours and was coming alright. Then the model shifted and turned on the PEI sheet. The print was ruined. Why isn’t the Siboor glu stick working on the CRM4 build tray?

If the print, with or without a brim, won’t stick to the bed then a raft isn’t likely to stick either. Have you been using the same type/brand/colour of PLA filament for all of these attempts IE the same roll?

I have been using the grey budget PLA from 3Dprintingcanada. The raft did stick until eight hours later when it became loose and spun to the side. The PLA I use sticks on my K1Max but the PEI sheet is different than the CRM4 PEI sheet. My K1Max is out of service temporarily

It’s unlikely to be an adhesion issue.

Check the z offset, flatness of the bed try differs file and different filament. One thing at a time.

I never use glue stick on any of my printers with pei. In good shape it should not need glue at all.

The z-offset is at -155. I washed the PEI sheet with soap and water. I then wiped it with isopropyl alcohol. I applied a layer of Siboor glue stick. The bed temp is 60 and the nozzle temp is 200. I am attempting a third print.

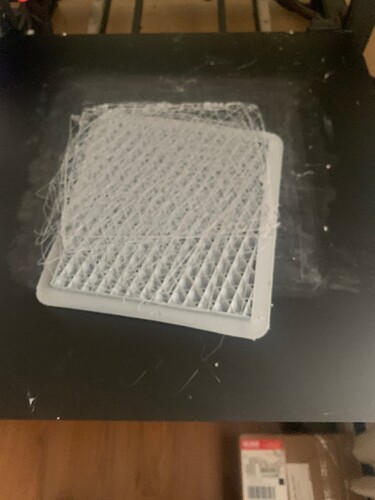

The z-offset is good because the raft forms and several layers build up. The print then shifts and the print fails. Here is the recent print failure. The PLA is adhering to the PEI sheet but for some reason the print slides on the PEI sheet resulting in a failed print.

Should I purchase a textured PEI sheet?

I had a third failed print. Nothing stays attached to my PEI. Do I need a textured PEO sheet for prints to stay attached? Is the smooth side defective for the CRM4 printer?

A smooth PEI sheet should hold very well. If he sheet has lost it finish then prints will fail. Try a different roll of filament, I have had trouble with cheap stuff failing to stick sometimes. Also try a different model to print and see id it holds, sometimes large surface prints are a problem. Forget the raft and use a LARGE brim and/or LARGE mouse ears on the corners of the print.

I have attempted using a brim. I am using Creality slicer and it does not give the option to increase the size of the brim. When I try printing a brim the printer makes an outline and that is all it does. It does not properly print a brim. I tried using Creality Print and adjusted the printer size however when I tried slice then print on my CRM4 the print was in the far back right corner and the printer made an unhealthy grinding sound. Here is a photo showing what happens when I attempt to print a brim using Creality Slicer…

I have increased my z-offset height to -165. Not sure how much higher I can go. Attempting a 4th print

Sounds like you printing a SKIRT instead of a rim. Try CURA instead of Creality Slicer, (CR slicer is an older version of Cura, cura is better) you can adjust the brim with that.

I selected the brim option so I don’t know why it was printing a skirt. Does Cura slicer support CRM4 printer?

Maybe not. I looked around and found this site that might help you. It shows how to create a Cura profile for the CRM4

Since there is a profile for your printer in Creality Printer are you sure there wasn’t an improper setting that caused the problem?

your z height seems very odd. You can slip a business card under the nozzle? Just?

Is the head dragging? you could try adding more z hop.

Did you check the bed is actually flat? The creality beds ship warped often.

You have tried different models and sliced? Actually try a bench.

different filament?

Is there drafts?