I’ve been asked to put together a toolkit for people building 3D printers and one of the things I wanted to add was a pen type digital multimeter:

Its features:

- Automatic Voltmeter/Ohmmeter selection (Voltmeter mode selected when 0.8V or more is detected across the leads)

- Continuity test

- Non-contact AC voltage detection

- Backlit display (actually a nice feature)

- LED for helping to guide the probe

- Less than $10 USD in quantity (they were less than $4 USD this past Thanksgiving/Black Friday/Cyber Monday sales cycle)

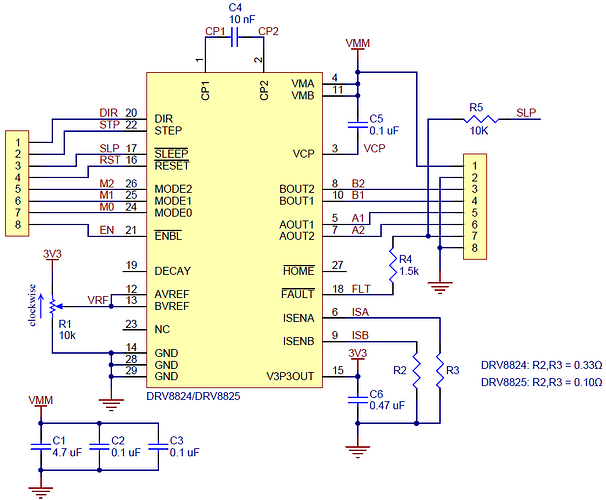

I thought it was a nice tool until I tried it with setting the current output of a DRV8825 using the built in pot. For at least the past five years, I’ve only worked with TMC2208 and later drivers that have the serial connection in which the current output can be set so this was something of a new experience for me.

My daughter has a school project in which she needed a continually rotating motor. I thought that since I have a ton of old 3D printer parts, I’d throw something together with an old 12V power supply, a RAMPS/Arduino Mega and DRV8825.

The problem came about when I tried to set the current with the pen multimeter - to set the current the voltage at the pot needs to be measured.

With the 0.1Ω sense resistor on the stepper driver module, the current output is defined as:

Ic = Vpot x 2

As noted above, the switching between the Voltmeter and Ohmmeter functions takes place at 0.8V. This is is 1.6A of driver current (or 19.2W) which is too much for the chip in this application as it goes into thermal shutdown after a couple of minutes of operation.

I found that the maximum current that could be run through the chip in this application is 0.8 to 1.0A (it’s hard to very precisely set the pot regardless of the Voltmeter you’re using). This basically matches what you would see in a 3D printer that was running this stepper motor driver module.

This means that while the cheap pen digital multimeter is well suited to my needs, it’s not going to be the only electrical tool somebody who manually sets their output current requires - they’ll also need a separate Voltmeter that doesn’t have a threshold value.

This is why I’m wondering how many people still set their driver currents with a pot and a Voltmeter?

Apologies for the long post, it kind of got away from me as I thought the context and example application were important.