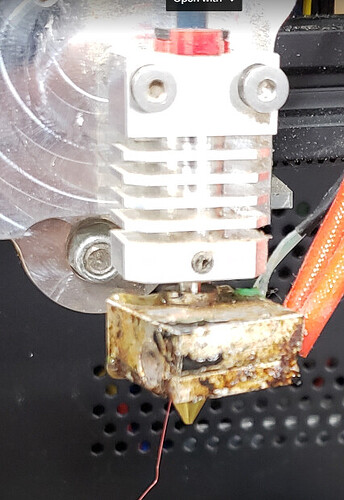

Hi! I am one of the technicians at 3D Printing Canada. I often get customers’ printers with leaking heat breaks, which means that the heat breaker got loose at some point. I recommend checking the hotend every 200 hours or so, mainly the Micro Swiss ones. How often do you guys check your heater block for leaks?

Never!

I use the “Luke Hatfield” trick in the hotend (replaced once a year,) and I never have trouble with leakage or jams. He came up with a simple but brilliant fix for any boden tube printer.

From my experience, Micro Swiss heater blocks are crap.

I’ve spent more money than I would have expected on replacement blocks as they really don’t stand up to any kind of long term use.

I’ve contacted Micro Swiss support numerous times on the issue and I have followed their instructions to the letter (leave the nozzle loose until heating to 225C) but after a few hours of use they start leaking as the nozzle and heat break loosen on their own.

When I look at the heater block threads under a microscope, I can see that chips are coming off them even though I only tightened the nozzle once and only loosened it when it started leaking.

To be fair, I print different materials, I go from PLA to ABS to PETg to Nylon and I think this exacerbates the problem. If you were to keep with PLA and keep it reasonably cool (200C to 210C) I think you would see better results and get longer life before they start leaking. In answer to the question @Tiago has posed, I’ve never had a Micro Swiss heater block more than 50 hours of printing.

It’s unfortunate because their hot end replacement for my Zortrax M200 is amazing - worked much better and lasted much longer than the manufacturer’s product.

I’ve gone to Revo nozzles and while they’re really expensive, I haven’t had any issues with them at all (they’re on two of my printers). I also use Chinese junk on two other printers and I’ve never seen a leakage problem at all - nothing like Micro Swiss.

Of course, YMMV.

I am surely going to check the trick.

Here is the approach I have taken with Micro Swiss heater blocks:

- I start by disassembling the heater block, heat break, and nozzle.

- I clean all parts using a brass brush and a heat gun until they shine.

- I heat the block to 220C.

- Then I screw back the heat break and tight as much as I can with a plier, caution not to break the neck.

- Now, I can screw the nozzle using a torque wrench (3N.m).

To check, I extruded 200mm of 1.75 PLA at 240C and >25 mm3/s.

The latest Micro Swiss heater blocks have a slightly improved design. I know some people are sanding down the heater block to improve contact between the heat break and the nozzle.

Everything you’ve listed here can be summarized as “Don’t buy Micro Swiss.”

I don’t use Micro swiss myself, never I have never needed to tighten a heat break or nozzle once installed. I went through Brass ones fast so I was forever swapping them now I am using XNozzles I have had it in the printer for ages, years now.

I have found this discussion interesting, and sort of validating. ![]() I am still running obsolete MK8 creality hotends, and they are serving me well. I have occasionally looked at Micro Swiss(and other likely better quality) hotends in the past, but really didn’t feel like spending that amount of money on replacing components that cost a fraction of that and are functioning fine. Now I hear that my obsolete hotends likely work better for me than a Micro Swiss would anyway. I find that strangely comforting.

I am still running obsolete MK8 creality hotends, and they are serving me well. I have occasionally looked at Micro Swiss(and other likely better quality) hotends in the past, but really didn’t feel like spending that amount of money on replacing components that cost a fraction of that and are functioning fine. Now I hear that my obsolete hotends likely work better for me than a Micro Swiss would anyway. I find that strangely comforting.

If you want to upgrade the hotend, I recommend integrated nozzles like the Revo’s or Microswiss Flowtech.

I must admit the Prusa xl nozzle is so easy to change. I have an Obsidian 0.6 and a brass. it is 2 seconds to change one screw and a plug.

There is nothing wrong with the stock hot ends from Creality for general printing of PLA.

I agree. As long as high volumetric rates are not the goal. Most exotic things I print is a little TPU and PETG.