So, thought the first:

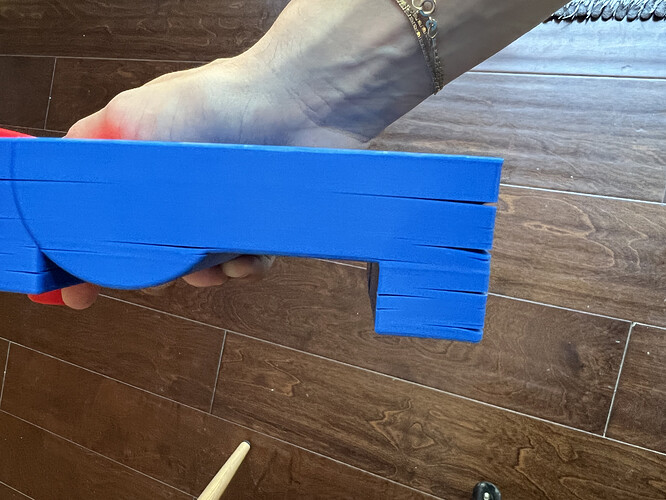

I’m guessing your printer isn’t enclosed, because that sure looks like differential cooling. ABS shinks as it cools. (Well, all plastics do, but styrenes shrink a lot.) The bottom layer of your print is as hot as the heat bed - presumably around 100 degrees - and the top layer is as hot as the nozzle - presumably around 260 - but in between the print will cool to the ambient temprature.

Without an enclosure, that ambient temperature is going to be room temperature. And, okay, depending on where you are that can be really warm - yesterday afternoon I switched on a printer and the ambient temps the nozzle/bed were showing was 31 degrees, which is awfully hot in a home! But even 31 isn’t really hot enough to keep the print from cooling.

Depending on the efficiency of the enclosure, you may or may not also need to heat it. I managed to enclose an Ender-5 and found that in summer that was enough but in winter, because the room is being vented to the outside and because the printer is right next to a concrete firewall, I needed some extra heat in the form of a heat lamp.

I can also see some major warping on the bottom; the best way I’ve found to deal with that is to leave the prints on the print bed in the enclosure and let the whole thing very slowly cool down to room temp. (Yesterday it meant letting a 3 hour print cool down for 4 hours.)

So, yeah, ABS is a pain in the butt to print. I’m using it because I’m joining parts together, and ABS can be solvent welded with less dangerous chemicals. Also, I’m then sanding the snot out of the parts and painting them so they don’t look like 3d prints, and ABS sands easier than other plastics. (Just make sure you’re wearing a mask so you’re not inhaling all the dust.) In my opinion, if you don’t need the ease of finishing and you don’t need the extra 20 degrees of temp resistance ABS has over PETG, there’s no real need to struggle through printing it.

As for PETG vs PLA, my personal experience is they’re about the same. CNC Kitchen and Tom Sandlander’s YouTube videos strongly suggest that as a single part PLA is actually stronger than PETG. I’m currently of the opinion that PETG’s main advantage is the 80 degree temperature resistance. Although, I do tend to use it for anything that will have screws driven into it.

Where are your toys failing? At joints, or are individual parts breaking? If the latter, rather than playing with exotic materials, have you tried just printing the parts stronger? The best way to make a part stronger is to increase the walls. For things that I want to be durable, I print with at least 4 walls and usually 6. With my 0.4mm nozzle, 6 walls makes the part 2.5 mm thick, which is pretty dang strong. (Increased infill helps a little, but common wisdom is that anything over 30% is a waste of plastic.

So, yeah. I’d take whichever filament you currently have on hand that isn’t ABS and try printing your part with 6 walls.

![]() ), but unfortunately it is being a pain to print with ABS. It cracks, it does not stick to bed… At this point, I’ve tried everything I could… I’ve watched multiple videos on YouTube, changed Cura settings, high temperature, low, glue, brim and everything else you can imagine. lol

), but unfortunately it is being a pain to print with ABS. It cracks, it does not stick to bed… At this point, I’ve tried everything I could… I’ve watched multiple videos on YouTube, changed Cura settings, high temperature, low, glue, brim and everything else you can imagine. lol