Well, the analysis has been interesting.

The part I was printing was basically the 14th more-or-less identical part, printed in the same material. They’re dividers for a storage case.

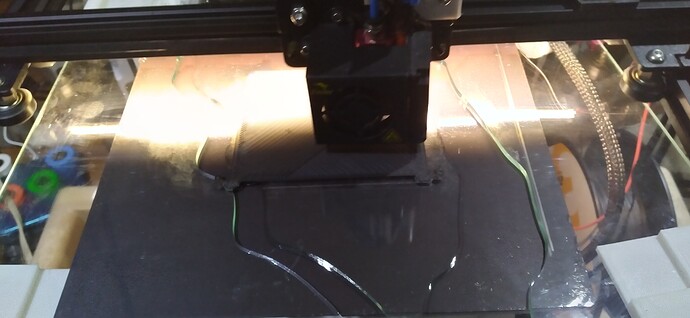

I use glue as a release agent because this particular PLA sticks to the glass something fierce. Without glue, it takes a spatula hit with a hammer at maybe a 3 to 5 degree angle to knock a print off even after the glass has cooled. Other PLA from 3DPC practically pops off on it’s own, but not this stuff. It’s the Black Matte PLA, for what it’s worth.

Having said that, I am conscious of not chipping the glass (hence the very low strike angle, but the removal of the glass fragments has taught me something.

Earlier in the week, I lost a pair of large prints when the print head scraped against the model’s infill and shifted the glass. It appears that the corner brackets I had been using for the last couple of months, printed in PLA-F (not flexible) had been getting loose. Perhaps they had shrunk? I don’t know what caused it, but they were a lot more easily removed than when I initially made them and it had reached a point where the glass was shifting during a print.

My solution was to put a single strip of double-sided Scotch Tape on the underside of the glass at each corner to make sure the brackets wouldn’t slip. The shattered glass was kind enough to stay put while the print finished, and when I examined it as the model was printing, I noticed the purge line was laid down at an angle and starting farther from the edge than it should have, indicating that the glass had shattered before the printing began.

That ruled out my initial theories that either the nozzle had impacted the glass, or the change in temperature between the glass and the hot PLA had caused a thermal fracture. Mind you, the facts that I’d been printing on this glass for months, that particular GCode had never resulted in an impact and the glass was designed for 3D Printers in the first place had me doubting those theories. That’s when I reached out to the forum as it was still printing on the last in-place glass fragment.

When it was done, I was surprised to learn was just how hard it was to get the corner brackets off the pieces of glass.

Based on that, I now think the brackets held are so tightly by that single strip of tape in the corners, that as the bed heated up and expanded, it appears to have literally pulled the glass apart.