actually looking at the drawing thats with that ad the nozzle is too short. the UM2 nozzles I have are 16mm long from the tip to the heatbreak end. these won’t reach if they used that drawing to make them. If you tried to screw the heatbreak in further to reach the nozzle it would end up putting the nozzle above the cooling fans shroud. Maybe the easiest thing is just get Volcano nozzles and cut them down to 16mm. you could thread them into a steel M6 hex nut and grind all the brass off until it was flush with the nut, clean it up and your done. no fancy tools and it would save a ton of money and time tracking these down

Once again we’re descending into madness! LOL.

I give up guys … this just isn’t worth the bother for me. As I’ve said I can print an adhesive decal in the right colours and that’ll do me fine.

Maybe someday when a nozzle is available that is a screw-on replacement I’ll revisit the issue. Would have been nice to play with one as the potentially finer detail is appealing.

As for making the font thicker … no. Fusion does let me arrange the letters around a curve that I define but other than choosing a particular font I can only select the character height. If I choose a thicker character then it just compresses the letters into the space and they bump into each other.

I have to share your disappointment. When I was making some HO turntables, I discovered I couldn’t get the detail I wanted (rivets) on the control cab shed that I was modelling has being made from corrugated iron sheets. It would probably do well for my father’s O gauge. Detail in HO is getting marginal. Detail in N must be near-impossible.

This is where resin printers find their niche.

I don’t know why they are so expensive. I can say the non copy V6 nozzles print far more detail accurately than copies. A print with a genuine nozzle (about 20$) prints more detail at 0.2 layer height than a cheap clone (about 1$ ) does at 0.1 layer height. Better faster cheaper you get any two.

The real deal: Better (more detail) Faster (faster prints for the same detail) you don’t get cheaper.

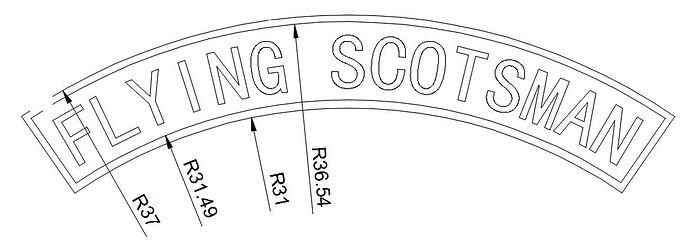

I’m trying to reproduce this. What is the radius of the text arc for the “Flying Scotsman” sign?

Now you’ve got me curious!

Here’s the font and size …

I’ve tried every font available and there were only 2 that fit in the space defined by the dark blue arc (32.18 mm)

Here’s the hand made model I want it for. The nameplate has to fit on that arc with the name on it. I can’t make it any larger or change the radius.

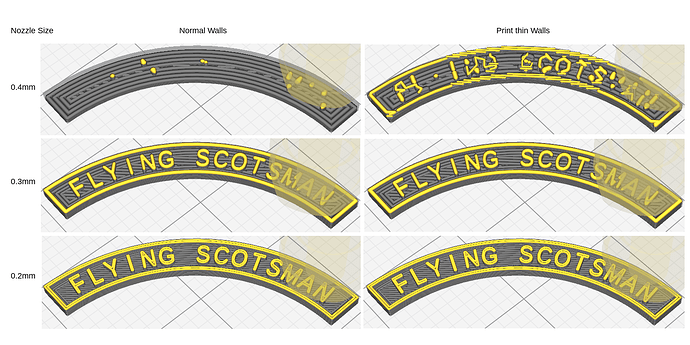

The sizes and positioning are probably not as precise. It was mainly done to see if I could get the Cura simulation to print the text without gaps or missing pieces.

I don’t know how to get rid of the ghost image of the print head. This is modelled with a 0.2mm nozzle.

I used OpenSCAD to create it and used the “offset” command to change the weight of the text and “scale” command to change the ratio of text height to text width. Basically, I eyeballed it so it won’t be as precise as the measurements you provided. Still, there was no way I could get a 0.4mm nozzle to play nicely.

I was hoping that by fiddling with the text height/width/thickness, I could get something printable with a 0.4mm nozzle, but it isn’t even close.

Can you try putting the model on a 20 or so degree angle on the bed and see if it will completely slice the text?

Good idea. I hadn’t thought of that. Angling it at 45 degrees makes the text look decent with a 0.3 mm nozzle, but 0.4mm is still hopeless.

But it might be enough to make a .2 work. I have this printer and might want to use the original print head with a small nozzle like that so I’m interested in seeing if this works. I see no advantage using the one I have with a volcano for the small nozzles. Mines printing with 1.2mm nozzle now at 60mm/s thats really what it’s for. The printer was more … consistent with the oem stuff and easier to dial in. Thats why I got the spare head.

I can make one of the .2 nozzles fit for him if the op wants to try but if it still won’t slice then its moot.

Wow, you guys are really into this! I like your dedication.

It looks like the .3 mm slice worked perfectly but I guess a nozzle that size is just as rare as a .2.

Maybe, in the absence of these nozzles, it might be best to just have someone resin print a pair and have it done with … puts us all out of our misery. Having said that I’m guessing that there’s different software to develop the Gcode (?) for a resin printer … no “slicing” involved?

This engine nameplate is the only one (of my 3 locos) that has a fixed set of dimensions … its radius has to follow the wheel size. The other 2 are linear and I just made them the length needed to get all the characters in using the font I wanted. They printed perfectly.