since the creality print slicer already has a k1 max profile i decided to try it for the first couple weeks of my new K1 max;

it lives down to it’s billing; it isnt in the same league with cura,prusa slicer and the 30 seconds i looked at orca slicer;

as an example ,creality print slicing step is done in two passes, 2 passes using a progress bar;

the actual printing is also done in 2 passes; there is the longer first pass which the printer reports as ‘time consumed, time remaining’, then when that completes the 2nd pass starts with it’s own ‘time consumed, time remaining’ BUT you wont know what that 2nd pass is all about until it is reported by the printer when it starts;

also when a model has a long name ( eg., long path) then the software does not report where that source is; it just truncates the path name leaving one to guess what the model really is;

also i am getting lesser quality on my end prints than i was getting with my flsun, one professional 3d reviewer reported getting lower quality g-code also from this slicer;

also the slicer does not have any ‘repair’ features such as cura mesh tools, prusa ‘fix with netfabb’ ( as well as the auto-fixes that prusa does when it loads a model

i can find nothing about adjusted e-steps on the k1 max , anyone know how ?

k1 max filament delivery system;

what a horror;

it looks to me like they had their phd designers and implementors doing the background work and had the secretaries do the design of the filament dlivery system;

i am currently bypassing the runout sensor and mulling upgrades;

kinks in the old “system” abound;

((that runout system can be easily fooled if you are so motivated))

You would only be able to do this if you install the open source firmware, other than that you are limited to flow in the slicer.

Same thing with the z-offset

If you have root access you can change e-steps (rotation distance in klipper) by editing the printer.cfg file under the specific stepper section. It is quite simple to do if you have mainsail or fluidd setup.

thanks for the replies on e-steps;

update: as expected that horrid filament delivery system failed; i tried many times to manually feed a particular filament ( slant cut of course, various twists, angles,straightens, attempts) ;

finally i just bypassed the runout sensor assembly;

the issue there is that assembly/sensor is tapped on each new print command ;

a message and stoppage “filament not detected” is issued;

thank goodness there is a ‘resume print’ option;

so it still functions;

with all the high tech behind this printer and intelligent designers, they sure farked up the filament delivery system;

if you notice, the default setup has the bend just before entry into the heater block via the feeder tube protruding higher than the natural top cover ; i print without that top cover ( also a design horror ) and that bend above the otherwise confined angle (with the top cover in place) is quite apparent

I have rerouted the bowden tube for a drybox so the filament doesn’t get hung up at the runout sensor so much any more but I find that I have to grab the bowden tube at the extruder to relieve the radius to prevent the filament getting hung up there while I’m pushing it through. Sometimes I just remove the tube at the extruder to get the filament fed in. Once the filament is in there I have no feeding issues.

like you Dave, i am bypassing the tube entirely and feeding directly into the extruder;

can fool the runout sensor if necessary using a small fragment of filament at the right time

once again on the retarded filament feed system that the K1 Max comes with…:

right now i am feeding directly from the spool into the extruder and bypassing the tube;

but i want to incorporate the drybox as a direct feed; my esun drybox looks like the feed angle it prefers is designed to feed from above its destination;

so it looks like i would need to remove the existing spool peg from the back of the printer unit and replace it with something 3 feet high and put the drybox on top of that ;

all of this with the top of the printer off (another design hiccup);

that sound right ? ( still bypassing the runout sensor);

and that of course strongly suggests getting more dryboxes to serve the spools-in-waiting

Vern.

I have a drybox. I am still using the bowden tube and runout sensor but I have unclipped the tube from the back of the printer to reach over my drybox (my drybox feeds out at the top). I don’t have any feed issues with the filament while printing. The only issue I have is loading the filament. The tight radius of the tube at the extruder causes the filament to hang up at the extruder when I’m manually pushing it in. I either relieve the radius a bit with my free hand or just pull it off and insert it again once the filament is in the gears.

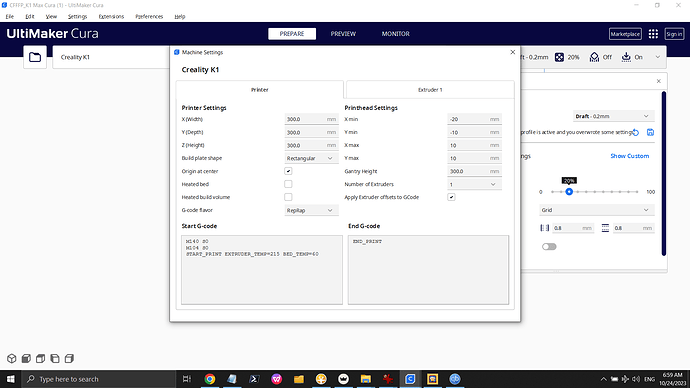

@matthew; is that cura profile you have been working on k1 or k1 max ?;

when i load it , it says “K1 standard” in the printer field: ( i am looking for the max…)

That doesn’t seem quite right, I am not worried about the settings profile, that will be correct.

Under the machine selection dropdown menu (where is says Creality K1), select the option that says “K1 Max”. Then you will be good to go, if this option is not there for you please re-download and import the K1 Max profile from the download page.

I just double checked with a brand new download and it is working fine from my end!

Matt

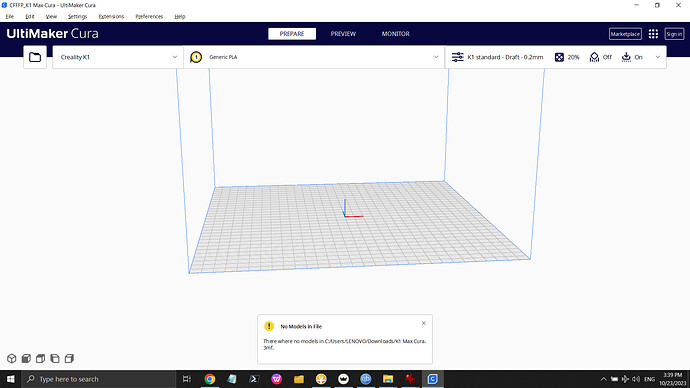

@Matthew; i redownloaded the .3mf file from printables.com and loaded it as a project in cura 5.3.0;

the behavior seems the same, note the image; the machine settings on first glance appear ok for the max

( altho i suspect i will have to check “heated bed”)

( and is reprap the correct g-code flavor ? or is marlin a better choice ? or does it make any difference ?)

thoughts ?

===> thanks

Hmm, yeah not sure what that is all about. Seems like the name is just different, everything else appears to be the same.

You don’t have to worry about checking heated bed, it is included in the start gcode.

@Matthew; is that reference to reprap rather than marlin ok ?

Yep that is no problem

brand new Cura 5.5 STILL is missing any of the creality K series , K1 and K1 Max !!

a caveat on the bypassing the designed filament feed ssytem;

i am doing so and will continue but need share some recent experiences;

- the actual inside extruder channel has a lip that the old tube sat on, so old-tube equals a better feed;

bypassing that tube introduces a snag point ( use a flashlight and you can see the issue );

when you do all this the old feed tube ( unless you remove it entirely) becomes a candidate for entwining the actual filament which is feeding directly into the extruder;

as a result recently i had a print where the drybox was pulled onto the build plate from some such entanglement;

i still believe i will go this way but just sharing… ( i Will remove that part of the now unused feeder tube system between the runout sensor and the extruder - design-wise the unit has way too much vibration, next to my flsun v400 delta unit it seems earthquakey;

in my case i added rubber feet under the rubber feet provided with the unit to dampen; it seems to help

here is a K1 Max Lid riser Vented ( addresses a design weakness )

interesting a printer printing it’s own upgrade ( recursive even);

Looks great! Thanks for sharing.