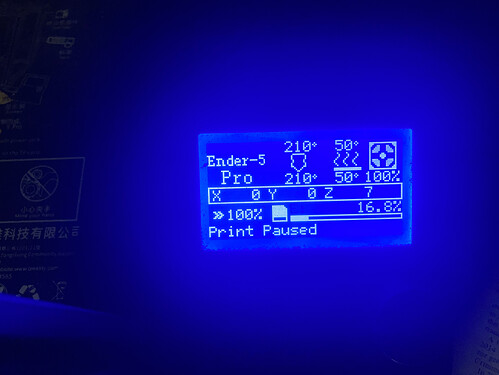

hello i am having trouble with my ender 5 pro, been sitting unused for the summer, tried doing a 3D Benchy print with generic pla the first layer prints fine and after that the feed motor starts clacking and the results are the odd string coming up off the first layer

That clicking noise coming from the feeder frequently means filament jamming, or not melting properly. Try cleaning the nozzle out and make sure the filament is dry.

.

I had already checked that and cleared the nozzle then checked it by extruding about a cm of filament using the movement control before I did the benchy, as I had tried one other part before and it had done even worse didnt think about the moisture though

What are your retractions set to? And have you checked that the heatsink cooling fan is spinning properly, sometimes this is caused by heat creep.

I did a bunch of checks and messed around this weekend. did a 100mm feed test and was dead on (maybe .1mm extra), disassembled the extruder found a piece of plastic stuck in the heat sink and removed that didnt fix the problem. Started a print and it completed the first layer before it started clicking so I aborted it and before the extruder could cool removed the filament to find it was flexing into an odd pigtail shape within the heatsink.

Kept trying and swapped filament roles to se if that made a difference still no change so i decided to try messing with the flow rate and turned it down, this seems to fix the problem if I reduce it to 90-95%. Unsure if this is the best way to fix it as that would then be reducing the integrity of the part as less plastic is going into the parts, but it is finally is printing.

yesterday i had three successful prints in a row shut it down and now I am having the same problem

Is this a Boden tube or direct drive extruder?

it is a boden tube type extruder

Look at this video. It shows a simple method that eliminates most Boden tube hot end problems. Worked for me. No problems in 18 month.

watched that video and that looks like it might be the problem. I quit pushing the tube all the way in after my first few prints because I had the tube melt to the filament but looking at what was happening to the filament after the jams i guess that it was backing up and then cooling too much to continue extruding…

You really need to use Capricorn tubing, i can take more heat, to make the short piece but can use any tubing for the rest. I have not had any trouble since I installed the short piece like the video.,

yes that is probably the best do you know if one can buy less than a full meter somewhere?

i pushed it down and that also solved the problem i was having with TPU

Most places sell it by the yard but it isn’t expensive. If you just use short pieces in the hot end that is enough to last several lifetimes (printer lifetimes). I like to change it out once a year to be on the safe side.

I got my Capricorn tube in the mail yesterday

how big did you print the washer?